Cattle Feed Production Line

A cattle feed production line is a complete set of equipment that processes various raw materials such as grains and grasses into finished feed pellets. Its purpose is to ensure that the nutritional needs of cattle are met at each stage of their growth.

- Output (T/H): 1-100

- Price (USD): 10,000-4,200,000

1–100 TPH Feed Pellet Production Line Cost & ROI

When building a cattle feed production line, the most pressing concern for clients is investment cost.

However, differences in production line scale, production targets, and livestock species often necessitate varying investment costs and payback periods.

- Construction Prices for Different Production Line Sizes: Based on RICHI’s experience, the investment cost for a small-scale cattle feed pellet production line (1-2 t/h) is typically around $3,000, for a medium-sized line (3-10 t/h) it’s approximately $50,000-$300,000, and for a large-scale line (12 t/h and above) it exceeds $250,000.

- Other Investment Costs: Production line construction is only one of the most significant components. Generally, the entire construction process also includes land purchase costs, plant construction costs, power system configuration costs, boiler and steam system costs, compressed air system costs, and waste disposal costs.

- Specific Payback Periods: The payback period for a cattle feed production line varies depending on its scale. Small-scale lines typically have a payback period of 6-12 months, medium-sized lines approximately 1-2 years, and large-scale lines 2-3 years.

Raw Material for Feed Production Line

RICHI cattle feed production lines are professionally designed to meet the raw material needs of cattle at different growth stages. They satisfy diverse raw material production requirements, eliminating the hassle of frequent equipment changes and effectively reducing investment costs.

Alfalfa

Ryegrass

Rice Straw

Forage

Corn

Soybean Meal

Beer lees

Matching Production Capacity of Cattle Feed Production Lines

Selecting the appropriate production capacity for a cattle feed production line is a complex process, with the main core factors being demand and profitability.

Below is a typical capacity matching table for your reference:

| cattle feed production lines for farmers | Professional cattle feed mill | ||||

| Number of animals raised (heads) | Daily raw material consumption (T) | Suggested production capacity (T/H) | Payback period (months) | Daily sales volume (T) | Suggested production capacity (T/H) |

| 100-200 | 1.5-3 | 0.5-1 | 10-18 | 10-20 | 2-3 |

| 200-500 | 3-7.5 | 1-1.5 | 12-20 | 50-80 | 5-8 |

| 500-1000 | 7.5-15 | 2-3 | 18-24 | 100-200 | 10-15 |

| 1000-2000 | 16-32 | 8-10 | 30-36 | 300 | 20-30 |

| …… | …… | ||||

| Note: Due to differences in individual investment budgets and overall needs, the process flow design of the production line may vary. Detailed information will be obtained during the consultation with the engineers. | |||||

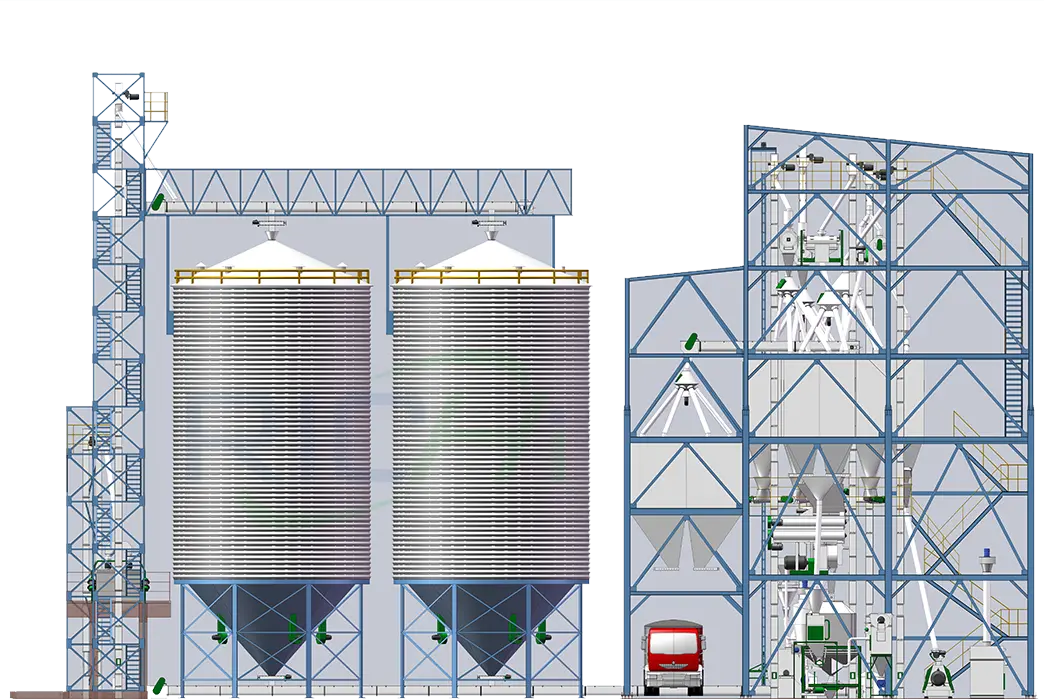

Workflow of Cattle Feed Pellet Production Line

RICHI cattle feed production lines can be custom-designed based on your raw material characteristics, production capacity requirements, and investment budget. Below are the six most common production stages.

Raw Material Processing

01

Raw material processing primarily removes impurities from raw materials such as corn, wheat bran, alfalfa, and hay, ensuring the raw materials are free of toxic molds and iron filings that could damage machinery.

Grinding

02

The processed materials are fed into a grinder and ground to a suitable fineness for consumption and digestion by cattle at different growth stages.

Mixing

03

Before pelleting, the ground raw materials need to be mixed with other materials to ensure they meet the nutritional needs of calves, fattening cattle, breeding cows, or dairy cows.

Pelletizing

04

The mixed raw materials are conveyed into a mixer where high-temperature mixing sterilizes and disinfects them. Then, they enter the pelleting chamber for forming and rolling the feed pellets.

Cooling and Screening

05

The pellets produced by the cattle feed pelleting machine are at a high temperature and need to be cooled to room temperature in a cooler. The finished pellets then undergo a final screening before packaging.

Packaging

06

This is the final step in the entire cattle feed pellet production line and an important step in making the feed look more commercially viable.

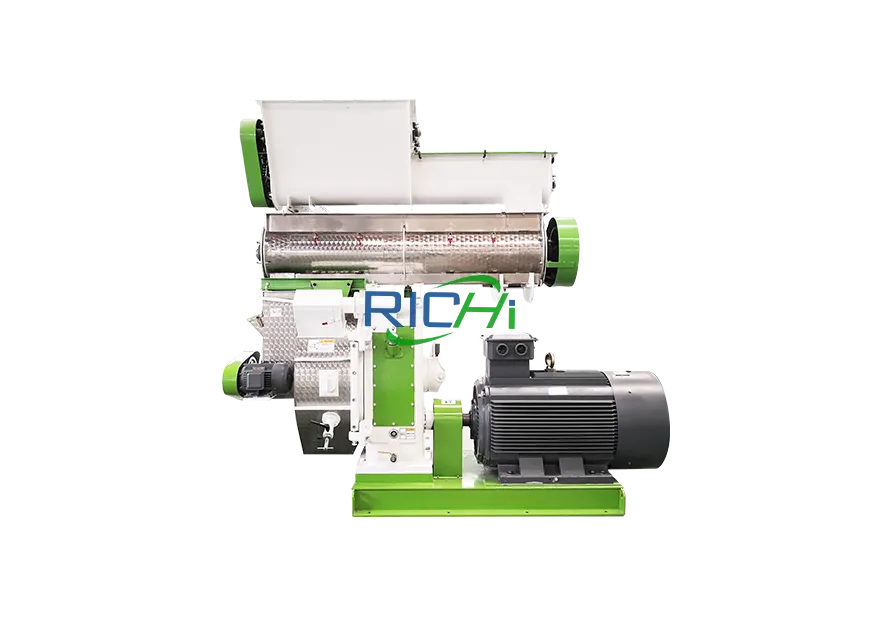

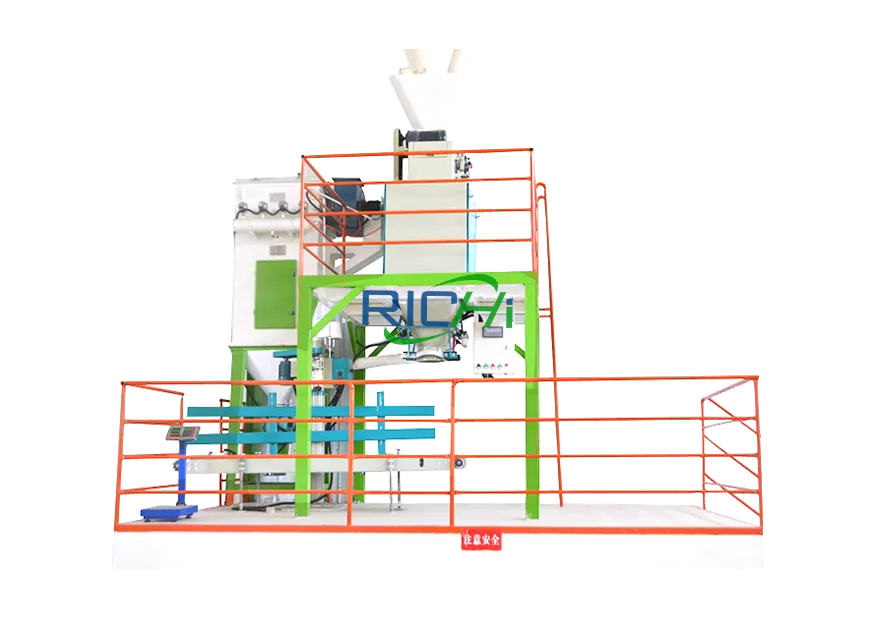

Equipment for Cattle Feed Production Line

RICHI manufactures all the equipment needed for a cattle feed production line and can customize equipment color, voltage, and overall layout according to customer requirements.

01

Drying Drum

Required for raw materials with a moisture content higher than 15%.

Diameter (m): 0.6-1.8

RPM: 3-12

02

Grinding Mill

Grinds various materials into powder suitable for cattle feed pelleting.

Capacity (L/Min): 50

Power (KW): 30-110

03

Mixer

Uniformly mixes various materials to ensure balanced nutrition in the finished pellets.

Capacity (kg/batch): 250-200

Power (KW): 4-30

04

Liquid Addition System

Adds liquid materials such as trace elements to the production line.

Capacity (L/Min): 50

Power (KW): 2.2

05

Professionally designed for the needs of cattle feed pelleting.

Capacity (T/H): 1-45

Power (KW): 22-355

06

Cooler

Cools the finished pellets to room temperature using ambient air.

Capacity (T/H): 3-5

Power (KW): 0.75

07

Rotary Classifying Screen

Separates broken materials from the finished pellets to ensure superior quality.

Capacity (T/H): 3-6

Power (KW): 1.5

08

Packaging System

Packages the finished pellets into packs of the required specifications for sale.

Capacity (bags/min): 6-8

Power (KW): 3

Video of Cattle feed production line

Our cattle feed production lines are customized to meet specific client needs. For example, some clients may be in a development phase, and our engineers will consider their growth trajectory and allow for future upgrades and modifications.

Below are examples of cattle feed pellet production lines we designed for a client in Uzbekistan and a cattle feed production line using alfalfa as a raw material, designed for a client in Argentina:

Cattle feed production line projects

Today, RICHI cattle feed production lines cover Saudi Arabia, Hong Kong, Uzbekistan, the United States, Argentina, and Germany.

15T/H Cattle Feed Pellet Production Line in Uganda

This feed production line actually produces not only cattle feed but also poultry feed. The client needed to establish two feed lines, but with our assistance, the problem was solved using only one production line.

- Installation Time (days): 65

- Equipment Price (USD): 415,000

5T/H Cattle Feed Pellet Production Line in Peru

This production line primarily uses ryegrass as its main raw material. It also includes other raw materials such as corn flour and soybean meal. The entire production line is used to produce cattle feed as well as ruminant feed such as sheep feed.

- Installation Time (days): 60

- Equipment Price (USD): 160,000

6T/H Cattle Feed Production Line in Uzbekistan

The main raw materials in Uzbekistan are cottonseed meal, corn, and sunflower seed meal. The client’s production requirements necessitated the ability to operate as a single unit or in pairs. Therefore, we designed this production line for the client, offering both operating modes.

- Installation Time (days): 50

- Equipment Price (USD): 185,000

10T/H Cattle Feed Pellet Production Line in the USA

The entire cattle feed production line uses raw materials such as corn and soybean meal, producing pellets with a diameter of 4-8 millimeters. We started construction and installation of this project in May 2019.

- Installation Time (days): 48

- Equipment Price (USD): 380,000

3T/H Cattle Feed Production Line in Argentina

The client specifically requested alfalfa as the raw material for cattle feed production, which placed high demands on the equipment. RICHI adopted the CZLH pellet mill, specifically designed for processing alfalfa with poor flowability, ensuring smoother pelleting for the client.

- Installation Time (days): 25

- Equipment Price (USD): 65,000

8T/H Cattle Feed Pellet Production Line in Germany

The customer’s daily output is 8 tons per hour, mainly using corn, oats, and rice bran as raw materials, resulting in low costs. The produced feed is primarily used to feed local beef and dairy cattle.

- Installation Time (days): 35

- Equipment Price (USD): 225,000

RICHI Services

30 years of industry expertise have allowed us to develop a service solution that best benefits our clients.

Primary Products and Services

Customized Design for Complete Feed Processing Plant and Biomass Pellet Production Plant.

enquiry@pelletmakingmachine.com

Consultation Services

Our professional consulting team is available 24/7 to answer your questions promptly.

Precision Manufacturing

Once the production process for your cattle feed line is finalized, we will promptly schedule production.

Detailed Design

Our engineers will create a customized cattle feed pellet production line tailored to your specific needs.

After-Sales Service

We will handle logistics, installation, commissioning, and training, and will conduct regular troubleshooting with you.

Customized Cattle Feed Production Line

Finding the most suitable cattle feed production line requires one-on-one understanding and consultation. Below are some commonly designed cattle feed pellet production lines for our clients:

Comparison of Beef and Dairy Cattle Feed Production Line

Beef cattle feed production line

Pellet Diameter (mm): 6-8

The feeding of beef cattle requires precise adjustments to the daily ration.

In the early stages, pasture is the primary source of feed for weight gain.

From the initial growth period onwards, protein, vitamins, and minerals need to be added. In the later growth stages, a 7:3 ratio of roughage to concentrate feed is required.

Dairy Cattle Feed Production Line

Pellet Diameter (mm): 4-6

Dairy cattle feeding involves transition from water and colostrum to solid pellets.

This process requires a shift from puppy pellets to fattening pellets. The proportion of hay and silage in the main feed ingredients will gradually increase.

Feed requirements differ during peripartum, lactation, and peak lactation in dairy cows.

Why Choose RICH?

RICHI focuses on building cattle feed production lines. From establishing our first animal feed production line to custom-designing cattle, sheep, and poultry feed production lines, we dedicate ourselves to ensuring your satisfaction.

With 30 years of experience in machinery manufacturing, we have built over 1000 feed production lines. Our engineers are committed to perfectly integrating equipment with the production line, making each line ideal for your pelleting needs.

Customized Solutions

Based on the breed of cattle you raise, RICHI will create the most precisely tailored cattle feed production line for you. This helps you maximize your profits in the cattle feed production industry.

Precision Craftsmanship

From the very first piece of equipment, RICHI Machinery has consistently maintained exceptionally high standards throughout. This ultimately results in a diverse series of high-quality, reliable products.

Experienced Expertise

Choosing RICHI means more than just choosing a set of equipment or a production line; it means choosing our accumulated over 30 years of global pelleting experience.

Frequently Asked Questions

Investing in a cattle feed production line is not a small amount, and the entire process requires comprehensive consideration. The following questions and answers may provide some insights.

1.What are the formulations for a cattle feed production line?

+

Cattle feed production can be divided into calf feed, late-stage fattening cattle feed, and breeding cow feed.

Calves:55% corn + 12% wheat bran + 24% soybean meal + 4% premix + 1.8% calcium carbonate + 2% baking soda + 1% salt

Late-stage fattening cattle:65% corn + 6% wheat bran + 20% soybean meal + 4% premix + 3% baking soda + 1% calcium carbonate + 0.8% salt

Breeding cows:58% corn + 14% wheat bran + 22% soybean meal + 4% premix + 1% calcium carbonate + 0.8% salt + appropriate amount of baking soda

2.How should I choose my own feed pellet production line?

+

The main factors are the number of cattle being raised and the production output. Typically, farmers choose feed based on their farming scale and daily raw material consumption.

Professional feed mills, on the other hand, need to consider daily sales volume and annual production capacity, while ensuring profitable operations and maintaining stable production.

If you have 20-100 head of cattle, a 1-2 T/H feed pellet production line is sufficient; for 100-500 head, choose a 3-4 T/H line; for 500-2000 head, choose an 8-20 T/H line; and for over 2000 head, a 20-100 T/H line is required.

3.Can I use a cattle feed production line if my raw materials include corn stalks, fresh hay, and cottonseed meal?

+

Absolutely. We will build a customized cattle feed production line based on your raw materials to maximize their utilization. Our CZLH model hay pellet mill is specifically designed for handling materials with poor flowability, helping you achieve smoother pelleting.

Additionally, we have designed the SZLH model animal feed pellet mill, which can process a wide range of raw materials to ensure that all your pelleting needs are met.

4.Can the currently installed cattle feed production line be upgraded in the future? Can I increase production capacity if I want to expand my farm?

+

Yes. You need to inform our engineers when finalizing the production line specifications, and they will design a space that meets your needs. This provides you with installation space for expansion and system upgrades.

If you are unsure which production line size to choose, please feel free to contact us.

5.How to choose a suitable cattle feed production line builder?

+

The company should have extensive experience in case studies and be an integrated manufacturer and trader.

Extensive experience ensures that any problems that arise during the construction of your cattle feed production line can be resolved promptly.

An integrated manufacturer and trader ensures timely equipment production and delivery. At the same time, it guarantees superior construction quality for the entire production line.RICHI fully meets the above requirements. You can also view more details on their YouTube channel.